About Polyurethane Film

Polyurethane Film: Customizable High-Performance Material

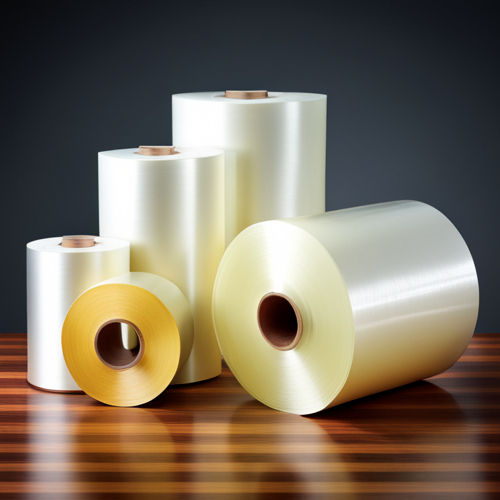

Polyurethane film is a versatile, high-performance material available in widths of up to 1200 mm. Its gauge (thickness) and color can be customized to meet customer-specific requirements, making it suitable for a variety of industries and applications.

Key Features of Polyurethane Film

-

Durability and Flexibility

- Known for its exceptional durability and flexibility, polyurethane film withstands abrasion and tough environmental conditions.

- It is an ideal material for long-lasting applications.

-

Customizable for Versatility

- The films ability to conform to various shapes ensures compatibility with diverse manufacturing processes.

- Customizable in specifications and colors, it provides solutions tailored to unique industry demands.

Applications Across Industries

- Automotive

- Used for protective layers and functional components.

- Medical

- Ideal for bonding materials in healthcare applications.

- Textiles and Packaging

- Ensures consistency and reliability in production.

Polyurethane films superior performance characteristics and customization options make it an indispensable material for modern industries, delivering tailored solutions that exceed customer expectations.

Superior Protection and VersatilityEngineered with advanced TPU, our polyurethane film delivers reliable leak protection and excels in demanding environments with high heat and UV exposure. Its flexible nature and customizable sizing ensure seamless integration into various projects, while the smooth, transparent finish contributes to both aesthetics and performance.

Custom Manufacturing Solutions from IndiaAs trusted exporters and suppliers in India, we offer bespoke polyurethane films tailored by size, thickness, and physical properties. Our manufacturing process uses precise extrusion techniques to guarantee consistent quality, high tensile strength, and prompt delivery for wholesale and bulk requirements.

FAQs of Polyurethane Film:

Q: How is polyurethane film produced and what makes extrusion the preferred shaping mode?

A: Polyurethane film is manufactured through film extrusion, where thermoplastic polyurethane (TPU) pellets are melted and shaped into thin, continuous sheets. Extrusion is preferred due to its ability to produce uniform films with precise thickness and excellent surface smoothness.

Q: What are the primary uses and benefits of clear, flexible polyurethane films?

A: Polyurethane films offer high transparency, flexibility, and exceptional leak protection, making them ideal for medical products, packaging, textiles, and industrial components. Their heat resistance up to 120C and UV stability further enhance durability and versatility in challenging environments.

Q: When should I choose TPU-based polyurethane film over other plastic films?

A: TPU-based polyurethane film is recommended when applications require superior tensile strength (up to 35 MPa), flexibility, heat resistance, and UV protection. It outperforms many other plastics in environments demanding resilience and long-lasting performance.

Q: Where can I source customized polyurethane films with specific lengths and sizes?

A: Custom polyurethane films in variable lengths and sizes are available directly from usIndias leading exporter, manufacturer, supplier, and wholesaler. We support bespoke dimensions to meet distinct project specifications.

Q: What is the process for ordering polyurethane film for bulk or wholesale requirements?

A: Ordering bulk polyurethane film involves selecting the desired thickness, length (up to 100 meters), and customization options. After specification confirmation, we oversee production and delivery, ensuring timely fulfillment for wholesale and export clients.

Q: How does the films heat and UV resistance affect its performance in industrial applications?

A: The films ability to withstand temperatures up to 120C and resist UV radiation ensures optimal performance in high-temperature and outdoor environments, reducing degradation and maintaining integrity over time.