About Polyurethane Automobile Parts

Polyurethane (PU) in the Automotive Industry

Polyurethane (PU) has emerged as a versatile and essential material in the automotive sector due to its durability, flexibility, and lightweight properties. It is widely used for manufacturing various vehicle components, enhancing performance and sustainability.

Applications of Polyurethane in Vehicles

-

Key Components

- PU is commonly used in:

- Bumpers

- Dashboards

- Seating components

- Interior trims

- Suspension systems

-

Material Properties

- Offers excellent resistance to abrasion, weathering, and chemicals.

- Can be formulated to achieve different hardness levels, suitable for rigid and flexible applications.

Advantages of Polyurethane in Automotive Design

-

Safety and Performance

- PUs energy-absorbing properties enhance safety by minimizing impact damage.

- Lightweight construction reduces vehicle weight, contributing to better fuel efficiency.

-

Production Efficiency

- The ability to mold into complex shapes allows for the efficient creation of custom parts, optimizing production processes.

-

Sustainability

- PU is recyclable and supports energy-efficient manufacturing, aligning with the automotive industrys focus on eco-friendly design.

Enhancing Vehicle Experience

Polyurethane contributes significantly to:

- Vehicle performance by optimizing functionality.

- Comfort through durable and ergonomic materials.

- Safety with impact-resilient designs.

Polyurethanes unique combination of properties makes it indispensable in modern automotive design, supporting cost-effective, sustainable, and high-performance production methods.

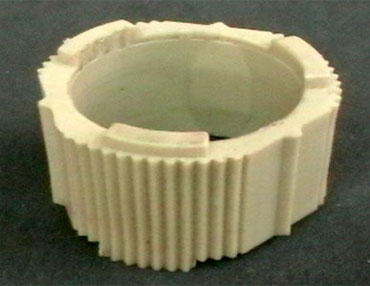

Exceptional Durability and PerformanceDesigned for challenging automotive applications, these polyurethane parts combine high tear resistance, impact strength, and long service life. Their ability to withstand extreme temperatures (-40C to +80C) and exposure to chemicals makes them ideal for the most demanding environments. Every part is manufactured through precision molding and finished to a smooth, polished surface.

Customizable to Your SpecificationsOur polyurethane components are fully customizable in size, color (yellow as standard), dimension, and packaging. Whether you require bushings, couplers, or dampers, each product can be tailored to fit specific vehicle models and mechanical systems. OEM services are available for unique applications or branding needs.

Easy Mounting and Low MaintenanceWith direct mounting options and compatibility with mechanical fasteners or press-fit installation, these components are straightforward to integrate into existing systems. Their self-lubricating properties and good corrosion resistance ensure smooth operation, reduced noise, and minimal maintenance for extended periods.

FAQs of Polyurethane Automobile Parts:

Q: How are these polyurethane automobile parts installed?

A: These parts support direct mounting and can be connected using either press-fit or mechanical fasteners, making the installation process straightforward for a wide range of vehicle types.

Q: What benefits do these components provide in the automotive industry?

A: The main benefits include high load-bearing capacity, excellent resistance to oil, grease, and solvents, effective noise reduction, long service life, and robust performance in varying temperatures from -40C to +80C.

Q: When should I opt for polyurethane parts over rubber or metal alternatives?

A: Choose polyurethane parts when you require superior tear resistance, high impact strength, better chemical resistance, and a longer working life compared to rubber or metal options, especially in demanding automotive applications.

Q: Where can these polyurethane parts be used in vehicles?

A: They are designed for use in cars, trucks, and commercial vehicles, serving as bushings, pads, couplers, dampers, and stoppers wherever mechanical durability and resistance to harsh environments are needed.

Q: What is the process for customizing a part to my specification?

A: Simply provide your dimensional and performance requirements, and our OEM services will handle design, molding, and finishing according to your specifications, including packaging and surface treatment options.

Q: Are these parts recyclable and environmentally friendly?

A: While the recyclability of polyurethane is limited compared to some other materials, these parts offer a long operational life, reducing the frequency of replacements and overall waste.