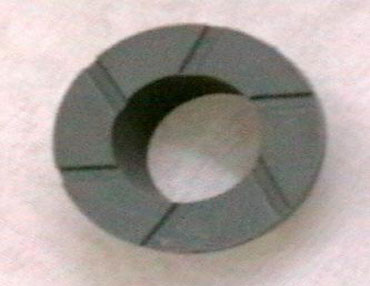

About Polyurethane Gear Leaver Bush

Polyurethane Gear Lever Bush

A Polyurethane Gear Lever Bush is an essential component in gear shift mechanisms, commonly found in automotive and machinery applications. This bush is designed to ensure smooth, precise movement of the gear lever while providing exceptional durability and wear resistance.

Key Features and Benefits

- Durability and Strength: Made from high-quality polyurethane, this bush offers superior strength and wear resistance compared to rubber, making it ideal for handling the high stresses and vibrations involved in gear shifting.

- Shock Absorption and Friction Reduction: The bush absorbs shocks and reduces friction, contributing to smoother gear transitions and minimizing noise during operation.

- Long-lasting Performance: Polyurethane is resistant to abrasion, oils, and temperature variations, ensuring a long service life even under demanding conditions.

- Improved Gear Shifting Precision: Polyurethane Gear Lever Bushes enhance gear shifting performance, ensuring a responsive and comfortable driving or operating experience.

Applications

Polyurethane Gear Lever Bushes are commonly used in:

- Manual transmission systems

- Machinery with gear shifting mechanisms

These bushes are ideal for automotive manufacturers and machinery builders, offering a reliable, low-maintenance solution that improves the performance and lifespan of gear systems.Superior Durability and PerformanceEngineered with high-quality polyurethane, this gear leaver bush provides exceptional wear resistance and durability. The low compression set and smooth glossy finish extend the product's lifespan, making it ideal for rigorous automotive use. The bush maintains consistent performance even under varying environmental conditions.

Effortless Installation and MaintenanceThanks to its press-fit design and tool-free, reusable installation process, this bush is convenient to attach or replace in any manual transmission system. Its standard OEM size ensures effortless compatibility, reducing downtime during maintenance or replacement.

Reliable in Diverse ConditionsThe bush operates reliably in temperatures between -40C and +80C, featuring stable performance in both cold and hot climates. Its resistance to oil, grease, chemicals, and corrosion makes it suitable for demanding applications while supporting low noise and self-lubricated functionality.

FAQ's of Polyurethane Gear Leaver Bush:

Q: How is the Polyurethane Gear Leaver Bush installed in automobile gear lever assemblies?

A: Installation is straightforward, requiring no tools. The bush utilizes a press-fit mechanism for secure placement, enabling quick and tool-free attachment or removal in manual transmission systems.

Q: What are the benefits of choosing a bush with 80-90 Shore A hardness and low compression set?

A: With 80-90 Shore A hardness, the bush maintains structural integrity and resists deformation under load. The low compression set ensures the bush retains its original shape, providing consistent performance and extending its operational life.

Q: When should the gear leaver bush be replaced in vehicles?

A: Replacement is recommended when noticeable gear lever play, unusual noise, or reduced gear shifting precision occurs. Thanks to its robust design and 100,000 cycle working life, frequent replacements are typically unnecessary under normal usage.

Q: Where can the bush be used, and which vehicles are compatible?

A: The bush is suitable for cars and light commercial vehicles featuring manual transmissions. It matches standard OEM dimensions for a range of popular automobile models and gear lever assemblies.

Q: What process is used in manufacturing this bush, and how does it affect quality?

A: The bush is produced via injection moulding, ensuring dimensional accuracy and a smooth, glossy surface. This process enhances strength, consistency, and provides a corrosion-resistant, self-lubricated finish.

Q: How does the chemical and weather resistance of this bush benefit its application?

A: Its resistance to oil, grease, and most chemicals, combined with excellent weather and corrosion protection, ensures reliable operation and longevity across harsh environmental conditions and demanding use.