About PU Textile Parts

Polyurethane (PU) in Textile Applications

Polyurethane (PU) has become a prominent material in the textile industry, thanks to its unique combination of flexibility, durability, and versatility. Its applications span across various sectors, including fashion, automotive, and industrial use.

Key Benefits of Polyurethane in Textiles

-

Durability and Resistance

- PU-coated fabrics offer excellent resistance to abrasion, water, and UV degradation.

- These properties make them ideal for outdoor applications like tents, upholstery, and sports gear.

-

Eco-Friendly Alternative

- PU is extensively used in synthetic leather production, providing a cost-effective and environmentally friendly substitute for traditional leather.

-

Enhanced Comfort and Performance

- PU's stretchability and conformability to various shapes make it perfect for fashion textiles, activewear, and footwear.

- It ensures comfort while maintaining strength and resistance to oils, dirt, and chemicals.

Versatility in Design

- PU's ability to achieve different textures and finishes broadens its utility in textiles.

- It is a favored choice for creating products that are both functional and stylish across diverse industries.

Polyurethane continues to revolutionize textile applications by offering unmatched versatility and performance, making it a go-to material for modern and innovative designs.

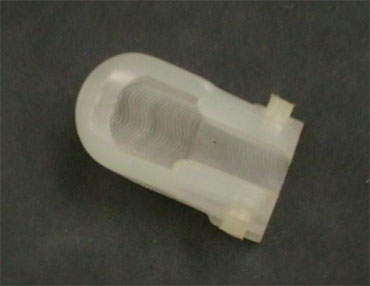

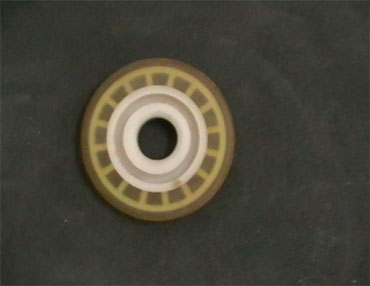

High Performance for Textile MachineryDesigned to endure the extreme demands of textile manufacturing, these PU parts resist both abrasion and impact. With impressive tensile strength and elongation, they're ideal for use as guides or buffers in modern textile machines, providing reliable support and extended equipment life.

Tailored Solutions and Seamless IntegrationCustomization options include dimensions, hardness, and design, ensuring a perfect fit for varied machinery. The bolted or fitted mounting options enable straightforward installation, while OEM support accommodates specialized requirements for manufacturers and suppliers.

Safe, Durable, and VersatileOperating efficiently in environments from -30C to +80C, these PU parts offer low compression set, flame retardant options, and resistance to corrosion and UV damage. Each component is leak protected and features a smooth, solid finish, packaged securely for shipment globally.

FAQ's of PU Textile Parts:

Q: How are these PU textile parts used in machinery?

A: PU textile parts are primarily utilized as guides or buffers in textile machinery, helping to reduce wear, absorb impact, and ensure smooth operation. Their robust abrasion resistance makes them ideal for continuous industrial use.

Q: What processes are involved in manufacturing these textile parts?

A: The parts are produced using high-precision injection molding, which allows for complex shapes, solid color patterns, and consistent smooth surface finishes. This process ensures each item meets stringent quality and dimensional specifications.

Q: When should I consider using flame retardant PU textile parts?

A: Flame retardant options are recommended for machinery operating in environments where fire safety is a priority or where compliance with international safety standards is mandatory. This feature enhances overall workplace safety.

Q: Where can these PU parts be installed in textile equipment?

A: These parts can be bolted or fitted precisely at points of high wear or movement within textile machinery, such as guiding or buffering elements. Their custom sizing makes them suitable for both new installations and replacement parts.

Q: What are the main benefits of choosing PU textile machine parts?

A: Choosing PU parts offers numerous advantages, including excellent wear and impact resistance, low compression set, corrosion and UV resistance, and the ability to function reliably across a wide temperature range. Customization further ensures compatibility and performance.

Q: Are size and hardness options available for these products?

A: Yes, each PU part can be customized in terms of design, dimensions, and hardness (Shore A 85 3) to cater to specific application needs. OEM support is also offered for tailored requirements.

Q: How are these PU parts packaged and delivered?

A: For best protection, each item is securely packaged in a polybag and carton box. As an exporter, manufacturer, and supplier from India, we offer global shipping and comprehensive OEM support for bulk and custom orders.