Talk to us

07313726335

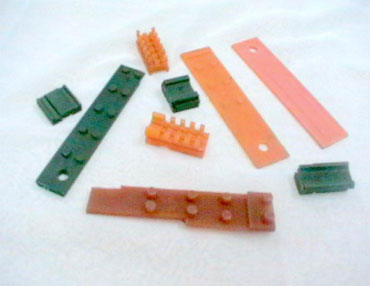

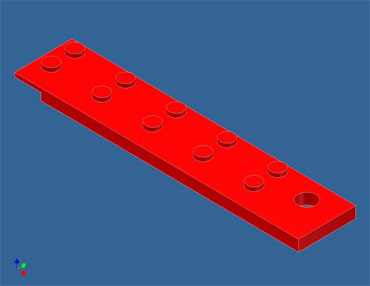

A Polyurethane Sulzer Break is a critical component used in Sulzer weaving machines, designed to control the shuttle's path and prevent it from over-speeding or causing damage during the weaving process. Made from high-quality polyurethane, the Sulzer break offers exceptional durability, wear resistance, and flexibility, ensuring reliable performance even in high-speed operations.

Shuttle Control: The Sulzer break applies controlled pressure to the shuttle, decelerating it smoothly as it completes its passage across the loom. This ensures better shuttle control and prevents abrupt movements that could lead to machine malfunctions or fabric defects.

Shock Absorption: Polyurethane's shock-absorbing properties help reduce noise, vibration, and wear on surrounding components, contributing to a more stable and efficient weaving process.

Durability and Resistance: The Sulzer break is resistant to abrasion, oils, and extreme temperatures, guaranteeing long-lasting performance in demanding industrial environments.

Weaving Machines: The Sulzer break plays a crucial role in Sulzer weaving machines, ensuring that the shuttle moves smoothly without causing damage or malfunctions.

Textile Manufacturing: Polyurethane Sulzer breaks are essential for improving the overall efficiency of weaving machines, enhancing the quality of woven fabrics, and ensuring consistent performance in textile production.

The polyurethane Sulzer break provides a cost-effective, low-maintenance solution that reduces maintenance costs, enhances machine performance, and improves fabric quality. By providing smooth shuttle control and absorbing shock, it ensures the longevity of both the weaving machine and the fabric produced.

Price:

Price 1.0 INR

Minimum Order Quantity : 1000

Plastic Type : PU (Polyurethane)

Density : 1.25 Gram per cubic centimeter(g/cm3)

Heat Resistance : Yes

Length : Standard/Custom as per requirement

Price 1.0 INR

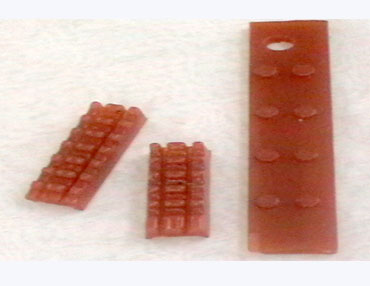

Minimum Order Quantity : 1000

Plastic Type : Polyurethane Elastomer

Density : 1.20 Gram per cubic centimeter(g/cm3)

Heat Resistance : Yes

Length : Standard as per OEM specification

Price 1.0 INR

Minimum Order Quantity : 1000

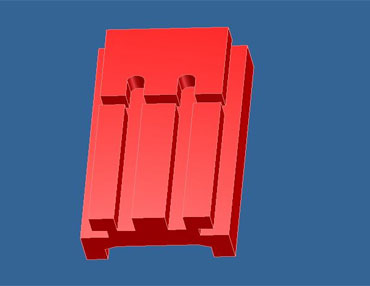

Plastic Type : Thermoplastic Polyurethane

Density : 1.12 Gram per cubic centimeter(g/cm3)

Heat Resistance : Yes

Length : Customized

Price 1.0 INR

Minimum Order Quantity : 1000

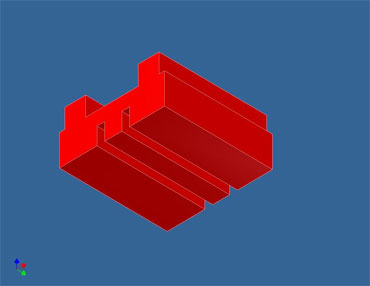

Plastic Type : Thermoplastic Polyurethane (TPU)

Density : 1.2 Gram per cubic centimeter(g/cm3)

Heat Resistance : Yes

Length : 150 mm