About Polyurethane Star Coupling

Polyurethane Star Coupling

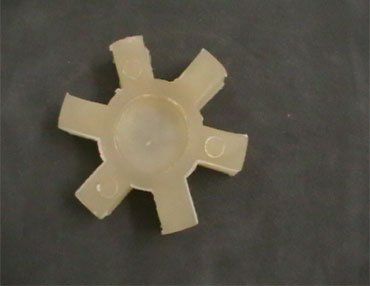

A Polyurethane Star Coupling is a flexible mechanical coupling designed to connect shafts and transmit torque in various machinery and power transmission systems. Made from high-performance polyurethane, these couplings are engineered to absorb shock, vibration, and misalignment, helping to protect connected components from wear and damage.

Key Features and Benefits

- Shock and Vibration Absorption: Protects machinery by reducing impact and vibration.

- "Star" Shape Design: Features a flexible insert with multiple pointed arms that offer flexibility while maintaining a strong connection between shafts.

- Abrasion and Chemical Resistance: Polyurethane provides excellent resistance to abrasion, chemicals, and temperature variations, making it ideal for demanding environments.

- Accommodates Misalignments: Helps compensate for slight misalignments between shafts, ensuring reliable operation.

- Noise and Vibration Reduction: Enhances overall system performance by reducing noise and vibration.

Applications

Polyurethane star couplings are widely used in:

- Motors

- Pumps

- Conveyors

- Robotics

Their simple design, ease of installation, and ability to provide efficient power transmission make them a cost-effective and reliable solution for industrial and commercial applications.

Exceptional Performance in Demanding ConditionsEngineered for reliability, this polyurethane star coupling excels in environments with temperatures ranging from -30C to +100C and offers high resistance against oils and chemicals. Its robust flexural modulus and excellent damping characteristics ensure vibration absorption and longer machinery lifespans, even under heavy-duty rotational loads.

Versatile Designs and Customization OptionsAvailable in various standard and custom sizes, our coupling inserts are injection molded and finished with a smooth, glossy surface. With color options like red, yellow, blue, or bespoke colors, adaptation to your brand and machinery aesthetics becomes effortless, without compromising on performance.

Ideal for Power Transmission ApplicationsPurpose-built for use as power transmission couplings, these star (spider) inserts are essential across a wide spectrum of industrial equipment. From general machinery to specialized applications, their superior mechanical and electrical properties offer a dependable interface between drive components, reducing wear and maintenance needs.

FAQs of Polyurethane Star Coupling:

Q: How is the Polyurethane Star Coupling used in power transmission applications?

A: The Polyurethane Star Coupling acts as an elastic insert between two metal hubs, connecting drive shafts and transferring torque while compensating for misalignment and reducing vibration. Its high damping properties and flexibility make it ideal for various machinery in need of reliable power transmission solutions.

Q: What benefits does the polyurethane material provide compared to other coupling materials?

A: Polyurethane offers significant advantages, such as excellent resistance to oil, chemicals, and UV radiation, as well as high tensile strength and durability. Its superior damping characteristics minimize vibration and noise, extending the service life of connected equipment and reducing maintenance frequency.

Q: Where are these couplings typically installed?

A: These star (spider) couplings are commonly used in industrial environments, including manufacturing plants, processing equipment, pumps, compressors, and any machinery where torque needs to be reliably transferred between shafts while allowing for some misalignment and shock absorption.

Q: What is the manufacturing process for the Polyurethane Star Coupling?

A: The coupling inserts are produced through injection molding, ensuring precise dimensions and a consistent, smooth, glossy finish. This process enables the production of both standard and custom sizes, tailored to diverse machine requirements and customer specifications.

Q: When should the coupling insert be replaced?

A: Replacement is typically recommended during regular maintenance intervals if signs of wear, hardening, cracking, or loss of elasticity are observed, or if the machinery exhibits increased noise or vibration. Thanks to the couplings long service life and high compression set resistance, replacements are infrequent under normal operating conditions.

Q: What are the key usage and installation guidelines to ensure optimal performance?

A: For best results, ensure correct fitment with matching jaw couplings, assess the couplings torque and speed ratings for compatibility, and periodically inspect for physical wear. Proper installation aligns the hubs and ensures the insert absorbs shock and compensates for shaft misalignments.